Markets/Materials

Gradient Coatings for for a wide range of materials and medical & IVD diagnostic applications

If your product has to manage small quantities of liquids, needs to control or analyze precise volumes, or has multiple liquid flows and mixing requirements – Surnetics can benefit you.

For microfluidic systems today, the need for precise and accurate control over fluid delivery, fluid transport, and fluid analyses within the device has forced most companies to develop systems using expensive pumps and control systems. These hardware items can exceed 80% of the system cost while also using up valuable space and energy requirements.

Surnetics surface energy gradient coating technology offers possible solutions for some common and not-so-common problems that you may be experiencing with your devices. We can help you develop an application-specific solution to these problems:

- Moving sample fluids to sensor area

- Mixing reagents and compounds for reactions

- Reducing variability in volumes and flow

- Reducing sample volume size

- Reducing cost of instrumentation and control equipment

- Lowering manufacturing variability

Surnetics has coating formulations that can be used on most materials, including:

Plastics: Polyester, Polycarbonate, COC, Polypropylene, Polyethylene, Nylon, Acrylic, Silicone Rubber

Metals: Gold, Copper, Silver, Nickel, Carbon and Stainless Steel.

Glass: Treated and untreated glass, silicon

Multiple markets can benefit from the flow control solutions offered by Surnetics.

_______________________________________________________________

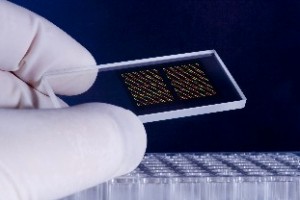

Diagnostics

Surnetics technology is an excellent fit for the diagnostics market. Many diagnostic systems under design are burdened with high equipment costs due to the expensive pumps and controllers needed to manage precise volumes of liquid flows. Future designs for handheld diagnostics, such as point-of-care or field testing products, will need to operate without any external pumps or controllers.

Surnetics can solve these problems to help you produce a low-cost diagnostic system with high performance and simple operation. Surnetics’ technology can be used in the following diagnostic products:

- In-vitro Diagnostics . . . . Lab-on-a-Chip . . . . Sensors . . . . Field Test Kits

- Point-of-Care . . . . PCR . . . . Microarrays and Microplates

_______________________________________________________________

Energy

Many energy technologies are sensitive to the presence of liquids. Whether the application needs fuel or water provided to one location or needs excess water removed from another location, control over liquid flows is vital to maintaining operating life and power densities in many of today’s energy technologies. Applications include Batteries, Fuel cells, and Solar panels.

_______________________________________________________________

Medical Devices

Using Surnetics’ coatings, implantable devices can offer important patient benefits – longer operating life, smaller less-intrusive devices, improved biocompatibility to name a few. For other medical devices, the ability to control fluid movement under low pressure, passive conditions can provide additional patient benefits.

- Implantable Devices

- Drug Delivery

- Wound Care

______________________________________________________________

Electronics and Power Device Cooling

Power from your device should be used to run your application, instead of having to cool your device. With electronic circuits and wafer features getting smaller while power densities increase, managing heat and temperatures is a primary concern for designers.

Surnetics’ technology offers a breakthrough for tomorrow’s devices. Our technology can be used to move liquids for cooling without pumps, leading to greater performance and longer life for your devices – all while reducing the cost of your system.

- Liquid-cooled devices

- Integrated circuits

- Aerospace components

- Communications devices

- Batteries, Fuel Cells, Solar Panels